Same Class, New Location

This May, we held our Certification of Sterile Compounding Facilities and Aseptic Isolators course. Heading into the class, there was some anxiety, because for the first time in 5 years, we were in a new location. That feeling quickly faded away as Bethlehem, Pennsylvania welcomed us with open arms. The food from local restaurants was delicious, and the Baker Company sponsored dinner at Bethlehem Brew Works was fabulous. The colonial charm of the city provided a familiar backdrop for our Maine-based staff. Overall, the city supplied a great experience for students and instructors alike. We are happy to be returning in October for our Fall offering of the course!

Inside the Classroom

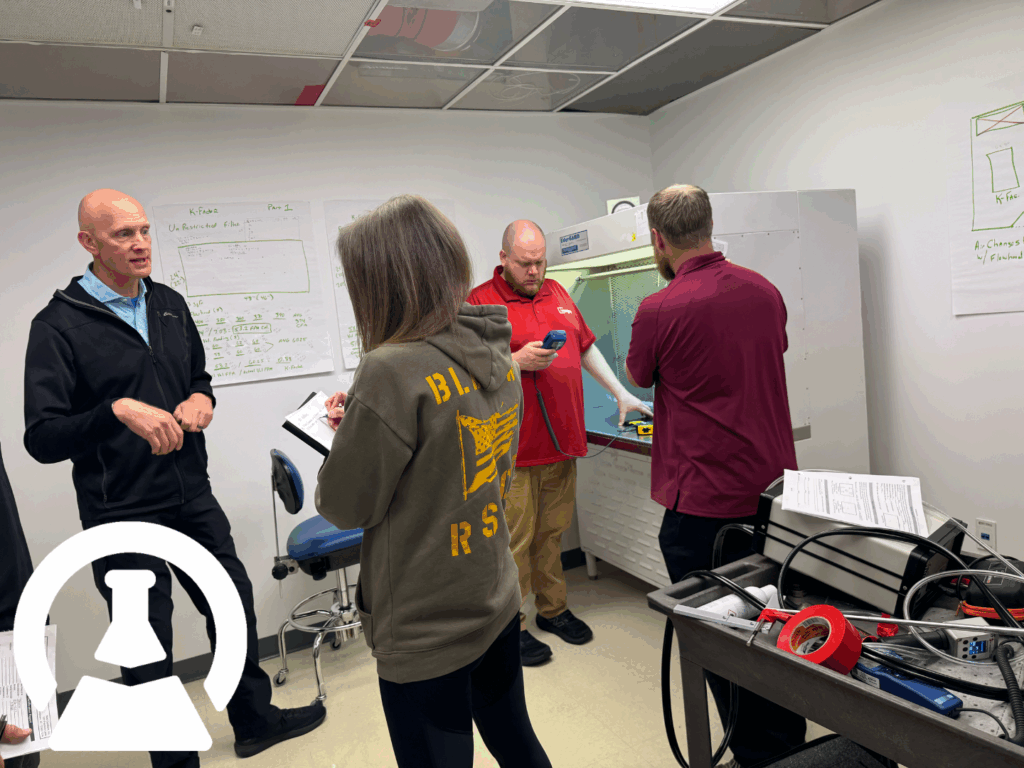

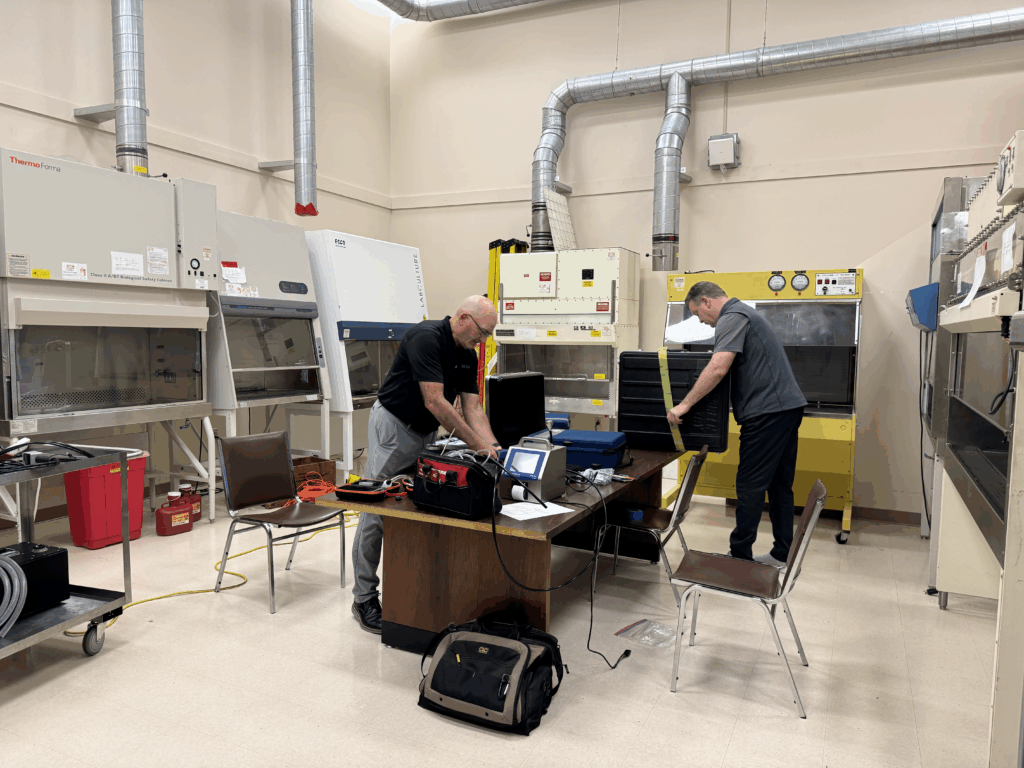

Students spent three days in the classroom and the lab reviewing facility design, environmental controls, and certification requirements for sterile compounding cleanrooms.

We kicked off day one with a deep dive into USP <797> sterile compounding standards and the NIOSH Alert on preventing occupational exposure to hazardous drugs. Participants examined how these and other standards shape facility design and operations. Then we moved into specific facility requirements and engineering controls aligned with these guidelines. The day continued with discussions on gowning requirements, and the importance of environmental monitoring of total and non-viable particles in USP <797> cleanrooms. The first day laid the groundwork for understanding the “why” behind certification protocols and how to approach them with confidence.

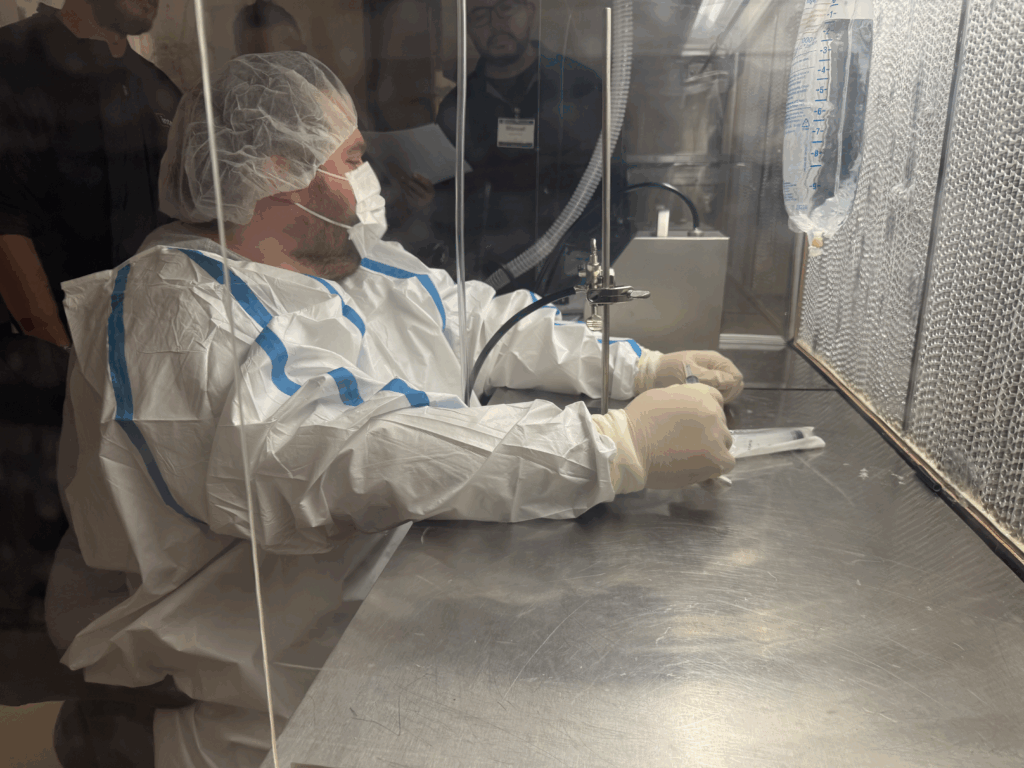

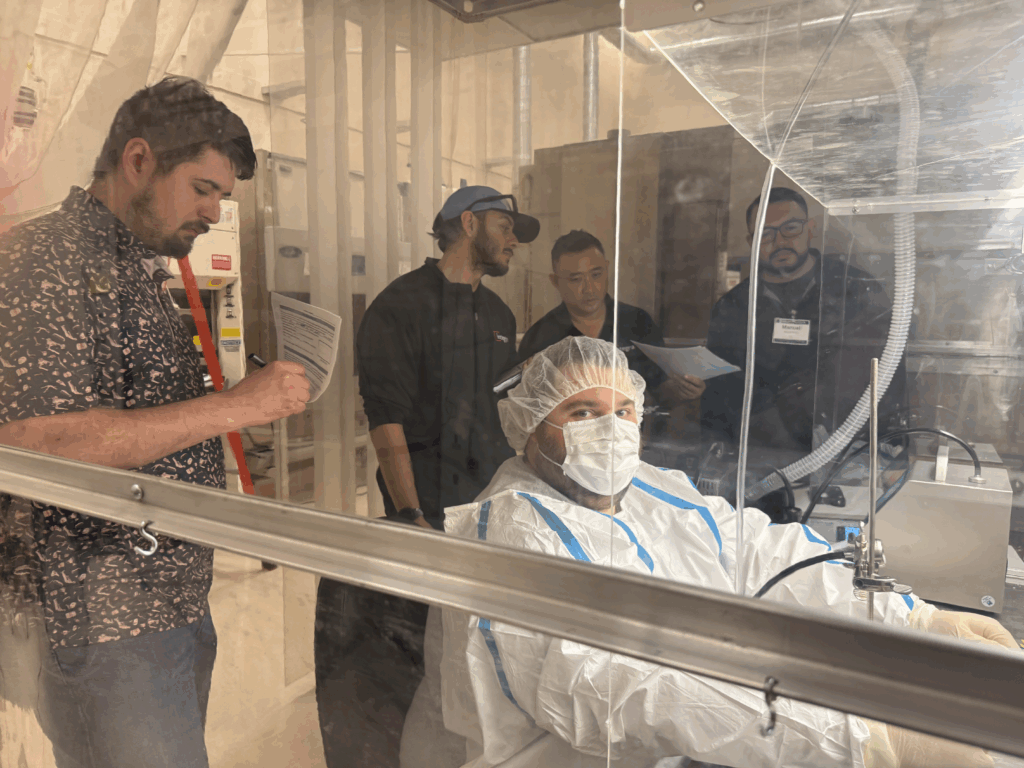

On day two, attendees suited up and stepped into the lab for workshops covering many of the concepts learned on the previous day. We also explored cleanroom concepts and core testing procedures, including airflow visualization, room segregation, and HEPA filter integrity testing.

Everything came together on day three. Activities centered on developing and executing test plans for real-world cleanroom scenarios, giving participants a chance to apply their knowledge in practical, team-based settings.

At the conclusion of the course, students were able to put what they learned to the test if they had signed up for the CNBT Sterile Compounding Facilities Exam. Those who passed the exam became Registered Certification Professionals for Sterile Compounding Facilities by the Controlled Environment Testing Association.

We’d like to give a big thank you to everyone who joined us! We are grateful for the opportunity to support your professional growth and contribute to keeping this industry strong and safe.

Interested in attending a future session? Registration for our Fall class is open on our website: www.eagleson.org/usp